Time:2021-06-09Views:

Compared with PCB, FPC has the characteristics of light weight, thin thickness, assembly time, and small size. It is more and more popular among developers, and its proportion in the market is increasing.

Prenatal treatment

There must be a complete and reasonable production process to make a good-quality flex pcb. From pre-processing before production to final shipment, every procedure must be strictly implemented.

In the production process, in order to prevent excessive opening and short circuits from causing low yield or reducing process problems such as drilling, calendering, cutting, etc. Flexible pcb board scrap and replenishment problems, and evaluate how to select materials to achieve customer use the best-effect flexible circuit board. Prenatal pretreatment is especially important.

Pre-natal pretreatment, there are three aspects that need to be dealt with, and all three aspects are completed by engineers.

The first is the flex circuits engineering evaluation, which is mainly to evaluate whether the customer's flexible printed circuit boards can be produced and whether the company's production capacity can meet the customer's board-making requirements and unit cost;

If the project evaluation is passed, the next step is to prepare materials immediately to meet the supply of raw materials for each production link;

Finally, the engineer processes the customer’s CAD structure drawing, Gerber line data, and other engineering documents to suit the production environment and production specifications of the production equipment, and then transfers the production drawings and MI (engineering process card) and other data to the production department and document control, Procurement and other departments enter the regular production process.

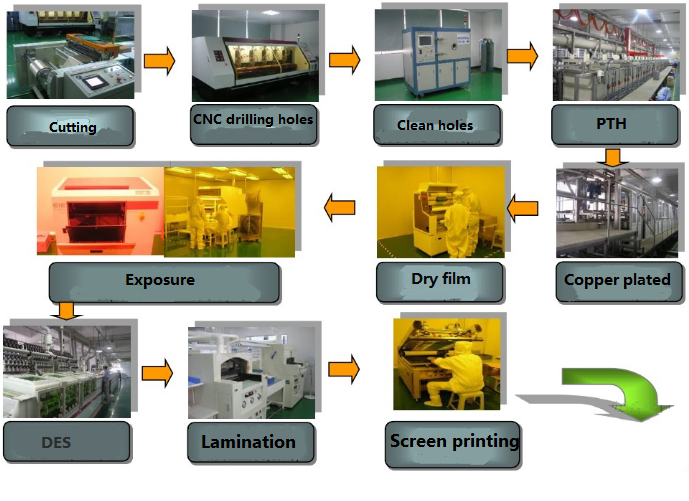

1.FPC board cutting

Cut whole rolls or large areas of raw material to size required for design processing

2.FPC drilling through holes

According to gerber file, the holes drilled on the circuit board. Mainly include: identification hole, assembly hole, positioning hole, via hole, alignment hole.

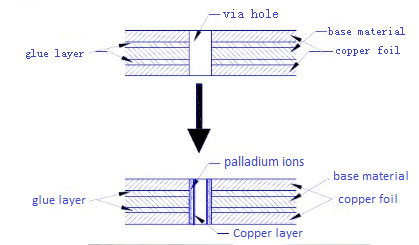

3.PTH (Plating Through Hole)

A layer of palladium ions is plated on the adhesive layer between the copper foils as a plating medium for subsequent copper plating.

4.copper plated

Increase hole copper thickness.

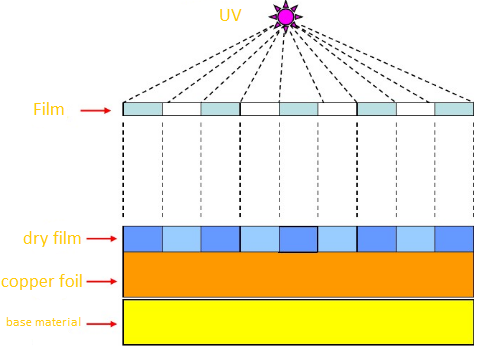

5.dry film----Coating of resist

A layer of photosensitive film is attached to the copper foil as a medium for image transfer.

6.exposure-----The formation of conductive patterns

Transfer the picture from the negative to the dry film by optical reaction.

7.DES Etching, resist stripping

Peel off the dry film that has not undergone optical reaction, and etch the exposed copper foil to form the required lines

8.Processing of cover film

A layer of protective film is pasted on the copper foil as the insulating layer of the circuit

9.Lamination

Use high temperature to melt the thermally hardened glue of the protective film, and use high pressure to squeeze the glue between the lines, and finally wait for the glue to cool.

10.Screen printing of FPC board overlay

Through the screen printing method, the ink is realized within the pre-designed screen printing range.

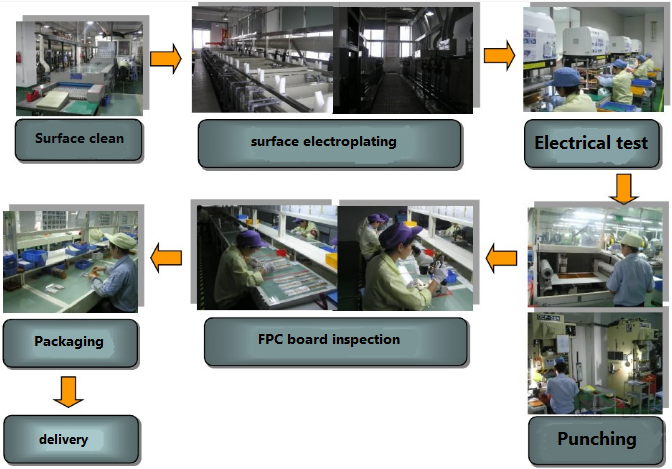

11.FPC surface electroplating

After removing the impurities on the surface of the copper foil, a layer of nickel-gold is plated on the exposed part of the copper foil to prevent the copper foil from rusting and improve the solderability and plug-in resistance.

12.FPC board guide hole

Targeting processing of pre-designed ET and punching positioning holes.

13.FPC Electrical test

By testing the impedance of a single line and the insulation impedance between the lines, to judge the real open and short circuit.

14.FPC board punching

Use die to punch the product into the product required by the customer

15.FPC board inspection and packaging

Remove products that do not meet customer standards, the flexible printed board FPC should be put into a polyethylene bag together with a desiccant such as silica gel and sealed at the mouth of the bag.