Time:2021-07-12Views:

Flexible circuit board, also known as FPC, is a type of printed circuit board with excellent flexibility. A piece of flexible pcb can complete the overall wiring work on one machine, and can be moved freely according to the space layout requirements, which reduces the wiring volume, realizes the integration of component assembly and wire connection, and promotes the development of electronic products. Small and thin development.

Flexible printed circuit boards is made of polyimide or polyester, which is light and thin, high density, high flexibility, bendable and foldable, and has advantages that other types of circuit boards do not have. Compared with traditional interconnect technology, flexible pcb board can withstand millions of times of bending, easy installation, good heat dissipation, and are favored by consumers.

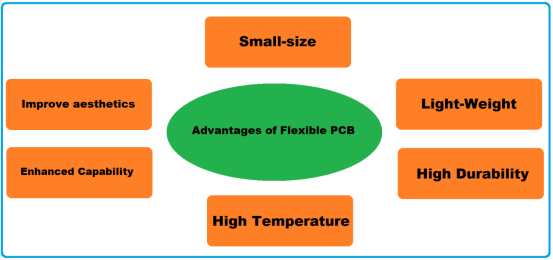

The advantages of flexible circuit boards can be summarized as:

① It can be freely bent, folded, rolled, and easy to connect;

② It can be moved, retracted and arranged at will, which is easy to reduce the volume of electronic products;

③ With good heat dissipation and solderability, it is easy to realize the integration of assembly and connection.

FPCBs can be divided into single-sided FPCBs, double-sided FPCBs, multi-layer FPCBs and rigid-flex FPCBs.

1.single-sided FPCBs

After the circuit is completed, a single-sided PI copper-clad material is used, and then a layer of protective film is covered to form a flex circuits with only a single layer of conductors. There is only one conductive layer, which is the most basic structure in Flexible Printed Circuits. It is light in weight and thin in thickness, and is suitable for consumer electronic products. such as inkjet cartridges for printers and memory for computers. Single-sided flexible boards have the lowest cost. When the requirements for electrical performance are not high and single-sided wiring is possible, a single-sided flexible board should be used. At XCF, We mainly make difficult FPC and high-difficulty FPC. We have no advantage in making such simple FPC.

2.Substrate generation double-sided FPCB

Two layers of single-sided PI copper clad laminate materials are used, and the adhesive glue for opening windows is used in the middle for pressing, so as to be pressed in a local area. A double-sided conductor circuit board with a two-layer separation structure in a local area to achieve a circuit board with high flexural performance in the layered area.Its advantage is that the signal transmission capability is greater than that of single-layer FPC. There are conductive copper on both sides and an insulating layer in the middle, which can be connected through the middle via hole to realize signal transmission.

3.multi-layer FPCBs

After multiple single-sided FPCs are pressed and drilled, the holes are subjected to metal oxidation treatment to make the through holes conductive, which becomes a multi-layer FPC. It not only has the advantages of single-layer FPC, but also doubles the number of high-precision lines through stacking.

4.rigid-flex FPCBs

It is a combination of flexible PCB board and rigid PCB board. It can both bend and bear weight, and has stronger performance and better stability than ordinary products. After the soft and hard are combined, a three-dimensional circuit board is formed, which optimizes the available space.

The applications of FPC

1.Mobile phone

Focus on the light weight and thin thickness of flexible circuit boards. It can effectively save the product volume, and easily connect the battery, the microphone, and the button into one.

2. Computers and LCD Screens

Utilize the integrated circuit configuration of the flexible circuit board, and the thin thickness. Convert the digital signal into a picture and present it on the LCD screen.

3. CD Walkman

Focus on the three-dimensional assembly characteristics and thin thickness of flexible circuit boards. Turn a huge CD into a handy companion.

4. disk drive

Regardless of hard disk or floppy disk, it is very dependent on the high flexibility of FPC and the ultra-thin thickness of 0.1mm to complete the fast reading of data. Either PC or NOTEBOOK.

5. latest application

The components of the suspension circuit of the hard disk drive (HDD, hard disk drive) and the xe package board. The wireless charging coil array concentrates the electromagnetic field in a certain area, reduces the space transfer consumption, and improves the power conversion efficiency.

As excellent thin and lightweight wiring material, XCF’s flexible printed circuits (FPCs) are not only contributing to smaller size and lighter weight electrical appliances, but also responding to high density component mounting for sensors and other applications. By enabling wiring for moving parts and three-dimensional wiring, arrays by folding and laminating, our FPCs are playing an important role as highly functional modules. Fully utilizing these advantages, our products are expected to be used in new fields that are viewed as future growth markets such as wearable devices, high-speed data transmission, robotics, medical application and more.