Time:2021-09-28Views:

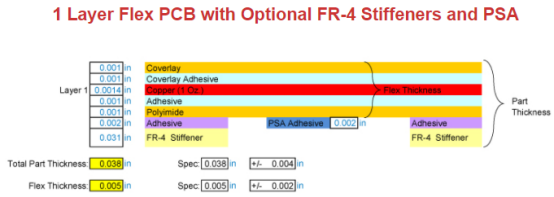

There are a number of basic material elements that constitute a flexible circuit board: a dielectric substrate film (base material), a protective finish (cover lay or cover coat), stiffener, shield, solder mask ink, pressure sensitive adhesive (PSA), not least, adhesives to bond the various materials together.

![]()

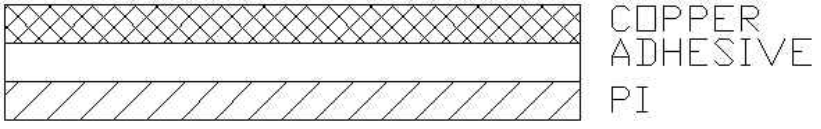

Three elements composed of soft board base material

1. COPPER FOIL

Generally can be divided into electrolytic copper foil and rolled copper foil.

2. ADHESIVE(ADH)

The ADH used for flexible copper clad laminates must be able to withstand a variety of process conditions and chemicals without delamination or degradation.

There are usually two Acrylic and Epoxy.

Thickness: 0.5mil, 1.0mil, 2.0mil; etc.

Generally speaking, Acrylic adhesives have excellent heat resistance and high bond strength. However, the electrical properties are not ideal, and the migration of copper will also be caused under high temperature environmental conditions.

Although the heat resistance of Epoxy adhesive is lower than that of acrylic adhesive, all its properties are well balanced and there is no problem for civilian use.

The issues to be considered when choosing glue are as follows: adhesion, flexibility, chemical resistance, heat resistance, moisture absorption, electrical properties, price.

3. Insulation material (POLYIMIDE & POLYESTER)

The two most widely used flexible insulating materials for FPC are POLYIMIDE(PI) & POLYESTER(PET)

POLYIMIDE

The price of PI is high, but its flame resistance is good, and the price of PET is low, but it is not heat-resistant, so PI needs to be used for welding.

The thickness of PI is 1mil, and the price is the cheapest. The conventional thickness is 0.5mil-5mil, and the price will increase beyond this range. The thicker the PI, the more stable the dimension will be, but for the cover film, the coverage will be worse.

Common thicknesses are: 0.5mil, 1.0mil, 2.0mil, 3.0mil, 5.0mil

POLYESTER

PET is an excellent film if it is not required to be used under conditions of high temperature resistance. The moisture absorption and dimensional stability of PET is better than that of PI film, and its colorless transparency is also a feature that PI cannot obtain. But when the temperature is 60-80 degrees, the mechanical properties of PET will be reduced. The current main use of PET is still at room temperature, and high-density circuits with fine pitches have not been used, and it is difficult for pet to reach the UL self-ignition rating.

Pet is generally used as a basement membrane, and is mainly used for reinforcement on flexible boards.

Coverlay;CC

Protective film refers to a material that is combined with the same insulating material (ie PI) as the substrate and adhesive. In order to play the role of protective glue, Mylar is covered on it.

The thickness of the protective film is generally 15um-50um.

The PI thickness of the protective film is generally: 12.5um, 25um, 50um, 75um, 125um. (0.5mil 1.0mil 2.0mil 3.0mil 5.0mil)

Stiffener;STF

Additional rigid material for reinforcement of the load-bearing element area and ease of installation.

The main materials are: PI, PET,FR4,aluminum sheet,steel sheet, etc.

Various reinforcement advantages and disadvantages:

The price of PI is high, but its flame resistance is good. And the price of PET is low, but it is not heat-resistant.

Use PI, FR4, aluminum sheet, stainless steel sheet for welding.

It is specially stated that PI, FR4, aluminum sheets, and stainless steel sheets must be used for the flex board that needs to pass Reflow.

The main purpose of reinforcement: In addition to PET, the other four types of reinforcement can be used for reinforcement at the lead sheet element. PET is generally only used for inserting the connector part, and PI reinforcement can also be used in this case. Metal reinforcement can also play a role in heat dissipation.

Adhesive glue between reinforcement and board

Commonly used adhesives are Pressure sensitive adhesive and hot pressing adhesive.

Hot Glue available in Epoxy and Acrylic.

PSA is a glue that can be directly pasted on insulating materials without hot pressing (similar to daily double-sided tape), and can be pasted many times.

Generally, PSA has two forms:

1) ordinary adhesive glue; such as 3M 9671, etc.

2) Conductive glue for electrical connection between board pads. Such as 3M9703; 3M9705 and so on.

The general thickness is 1mil, 2mil, 5mil.

When using PSA as an adhesive, be sure to drive out air bubbles. In order to prevent the board from being deformed or wrinkled due to foaming in the subsequent process.

PSAs are less reliable due to their low chemical resistance and creep resistance. For high reliability products, thermosetting adhesives should be used.

Shield

The main types of shielding layers currently used are:

A. Silver paste (low cost and poor bending resistance)

B. Black silver film. Its advantages and disadvantages are: bending resistance, good electrical conductivity, small specific gravity, but high cost, not easy to store.

Solder Mask Ink

Solder mask ink types are: developing type (LPI), UV curing type, heat curing type.

Liquid Photo-Imaging (LPI) uses screen printing or spraying to coat and cover the etched winding circuit board with liquid photosensitive ink. After drying, exposure, development and other imaging transfer methods, the exposed connection pad and protective film are formed.

The coating protection type is UV type and heat curing type, which are screen printed on the circuit board and cured by infrared heating or ultraviolet light to form a permanent and non-abrasive thin protective coating.