Time:2021-03-05Views:

As the name suggests, an 8-layer rigid-flex PCB is made with 8 conductive copper layers. If these copper layers are left unprotected, they can start to deteriorate, rendering the PCB ineffective. Therefore, to stand the test of time, PCB manufacturers use reliable surface finishes to extend the life of these critical components. Of the several surface finishing methods available, two of the most commonly used are briefly discussed in the blog.

Learn about HASL and OSP

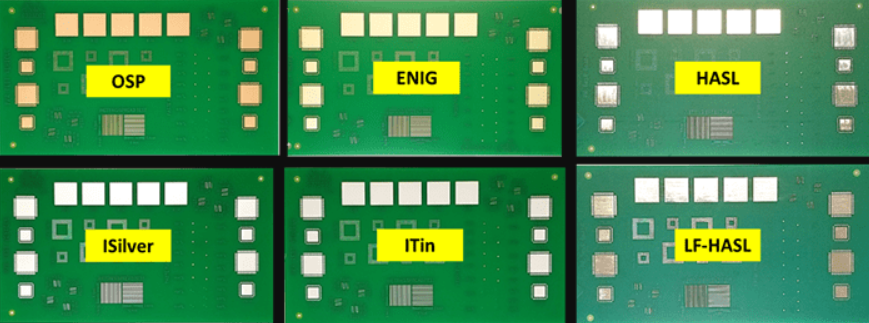

(HASL) Hot Air Solder Leveler and OSP (Organic Solderability Preservative) are widely used surface treatments that can be used to coat 8 layers of rigid flex boards. Both methods provide complete protection of copper circuits from aggressive industrial environments. Also, these surface finishes provide a solderable surface when assembling various tiny components on the board.

HASL – In this method, an 8-layer rigid-flex PCB board is dipped into a molten alloy of tin and lead. After dipping the board and removing it from the molten solder, use an air knife to remove the excess solder. The result is a very thin layer of solder on the board surface that protects the board's underlying components. This method is popular because of its many advantages, such as low cost, ease of application and rework, good bond strength, and long shelf life.

OSP – Compared to several other surface preparation methods, OSP is considered the most environmentally friendly coating method. During this surface treatment, a water-soluble surface treatment agent is used to provide a protective coating layer on the hard flexible surface. The organometallic layer protects the copper layer from corrosion and other adverse environmental conditions. The advantages associated with this method include: cost-effectiveness, simple process, good solder mask integrity and finish.

In addition to these two common methods, PCB manufacturers also use immersion gold, immersion silver, immersion tin, and electroless nickel immersion gold (ENIG) to provide enhanced protection for copper layers and components. After analyzing the method of assembly, the components used and the typical field of application, the type of surface treatment is selected.