Time:2023-06-26Views:

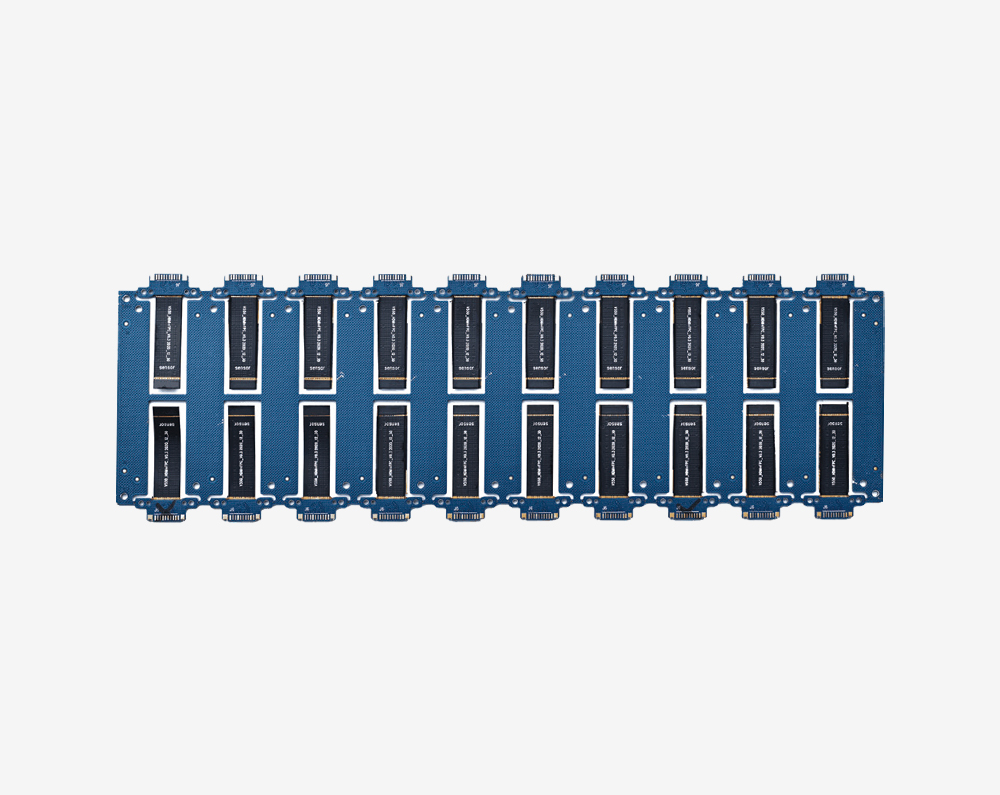

Quality is the foundation of the enterprise, and it is also the hard cornerstone of development. The first level of strict testing and defending quality is to select high -quality plates! If PCB manufacturers want to control the quality of the PCB board, how to control it?

If we want to control the quality of the PCB board, we must have a quality control system, which is commonly referred to as ISO9001. Generally, the concept of the quality control system is real -time quality measurement and supervision. When one thing has a unified measurement standard and supervision standard, it is easier to do it.

To control the quality of the PCB board, we must first start strict quality inspection from raw materials. Any defects must be registered and reported in time, and solutions are proposed. Only by ensuring the quality of raw materials can it be possible to get high -quality PCB boards. If the quality of the raw materials is not guaranteed, the PCB boards produced are likely to occur in various problems, such as foam, layering, cracking, warming, and uneven thickness. Therefore, we must strictly control the raw material and provide a guarantee for subsequent production.

While ensuring the quality of the raw materials, we must also pay attention to the problems that may occur during the production process. PCB circuit board manufacturers must conduct quality inspection and inspection of each process in the production process to ensure that each process has operating procedures to facilitate the comprehensive control of PCB quality.