Time:2023-06-27Views:

In fact, it is not. This is naturally a purpose. Nowadays, with the improvement of the system rate, it is not only the timing and signal integrity of high -speed signals. At the same time, the electromagnetic interference caused by high -speed digital signals in the system is also very prominent. The electromagnetic interference generated by high -speed digital signals will not only cause severe mutual disturbance inside the system, reduce the anti -interference ability of the system, but also produce strong electromagnetic radiation in the external space, causing the system's electromagnetic radiation to emit The products of board manufacturers cannot pass the EMC standard certification. Multi -layer PCB plate radiation is a relatively common source of electromagnetic radiation. When the non -expected current reaches the edge of the ground layer and the power layer, edge radiation occurs, which shows that the ground and power noise generated by the insufficient power of the power supply. The cylindrical radiation magnetic field generated by the perceptual over -perforated, which radiates between the layers of the circuit board, and eventually meets the edge of the circuit board. The band line reflux current carrying high -frequency signals is too close to the edge of the circuit board. In order to prevent these situations, the PCB line boards are surrounded by a 1/20 wavelength hole distance to a circle of grounding to form a hole to form a holy shield to prevent TME waves from radiation.

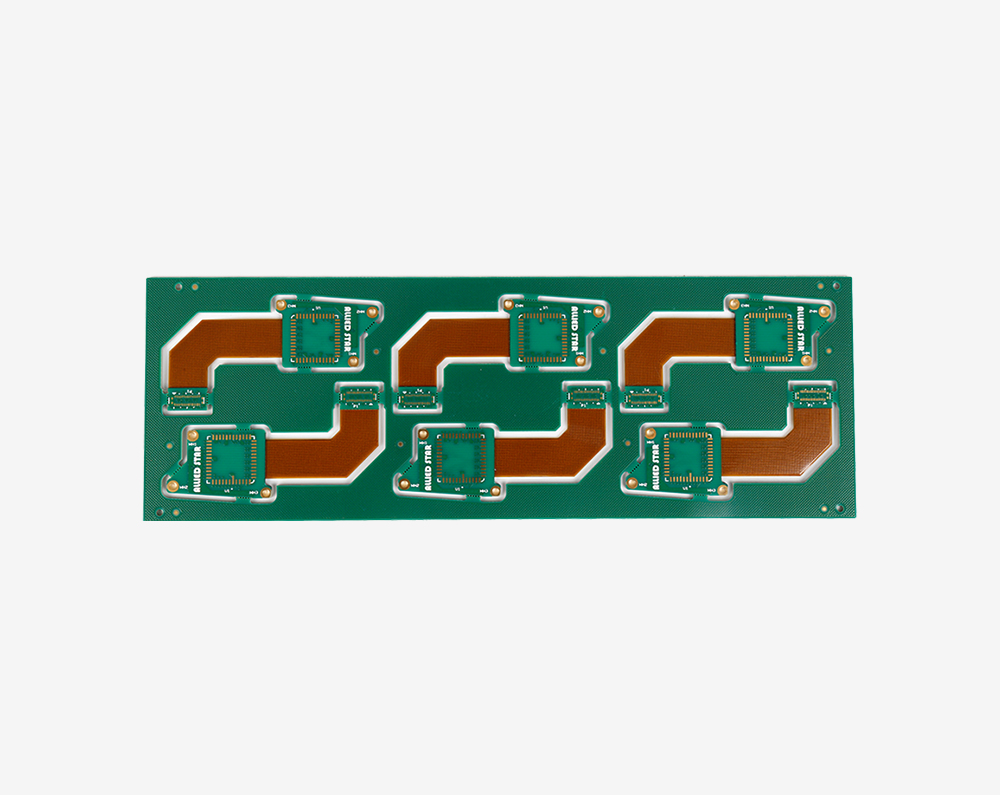

For microwave circuit boards, the wavelengths of the wavelength have further become smaller, and because the PCB production process is now, the spacing between the holes cannot be done very small. At this time The role of microwave boards is not obvious. At this time, the PCB version of metal -based edging process is needed to surround the entire board with metal, so that the microwave signal cannot be radiated from the PCB board. Border craftsmanship will also lead to increased PCB production and manufacturing costs a lot. For radio frequency microwave boards, some sensitive circuits, and circuits with strong radiation sources can be designed with a shielding cavity welded on PCB. The PCB line board must be added with the "over -hole shielding wall" when designing The wall of the cavity is close to the ground. In this way, a relatively isolated area is formed. Only after confirming that it is correct, we can send multi -layer line board manufacturers for production.