Time:2023-07-06Views:

Since the day of LED, the problem of heat dissipation has always been a major problem that plagues manufacturers. If the node temperature of the LED exceeds 85 degrees, it will cause chip failure and fluorescent powder to oxidize, causing light failure, and the heat dissipation performance directly affects the life of LED lamps. The aluminum substrate has the characteristics of high thermal conductivity, low thermal resistance, voltage resistance, light quality, and anti -oxidation. The advent of LED aluminum substrates has brought new solutions to the heat dissipation problem of the product.

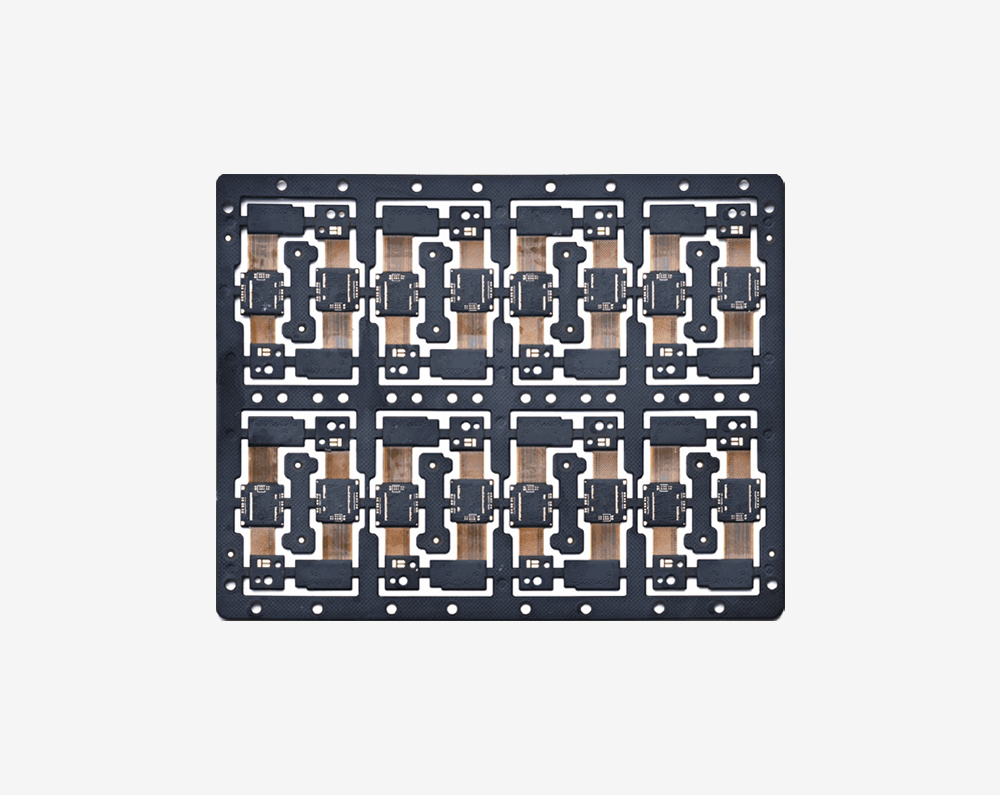

The double -sided aluminum substrate is composed of the circuit layer (copper foil), thermal conductivity insulation layer, and the metal grassroots structure. The working principle is to be packed on the circuit layer on the surface of the power device. The grassroots, then pass the heat from the metal grassroots to the heat to achieve the heat dissipation of the device. The aluminum substrate is widely used in the LED industry, with the scope of LED street lights, spotlights, wall lamps, buried lights, LED fluorescent lights, etc. In 1969, the Japanese company first invented the manufacturing technology of aluminum substrate. In 1974, it began to be applied to the STK series of power amplification and hybrid integrated circuits in 1974. The development and development of aluminum -based copper plates in my country began in 1988. In 1990, the state -owned factory completed the factory -level design and setting of the universal aluminum substrate, and established the first domestic aluminum -based copper plate production line and put into operation.

The quality of the aluminum substrate directly affects the quality of the finished LED lamp. Due to the low entry threshold and lack of core technologies, the industry standards are incomplete. At present, the domestic aluminum base market has a mixed product quality and mixed fish. The thermal conductivity of the aluminum substrate does not have specific measurement specifications. The aluminum -based copper -covered copper plate thermal conductivity produced by different manufacturers is relatively large. The quality of the products produced by some aluminum substrate enterprises is difficult to maintain, and the measured data of the thermal conductivity coefficients does not match the nominal data. At present, there is a certain gap between the technical level of domestic aluminum substrates and the internationally internationally, lack of support for core technology, general low -end homogeneity of products, low -quality and poor products occupy the market, and there are few high -end products. Enterprises formed a vicious competition in the price war, and the price under price caused the industry's profit.