Time:2023-07-06Views:

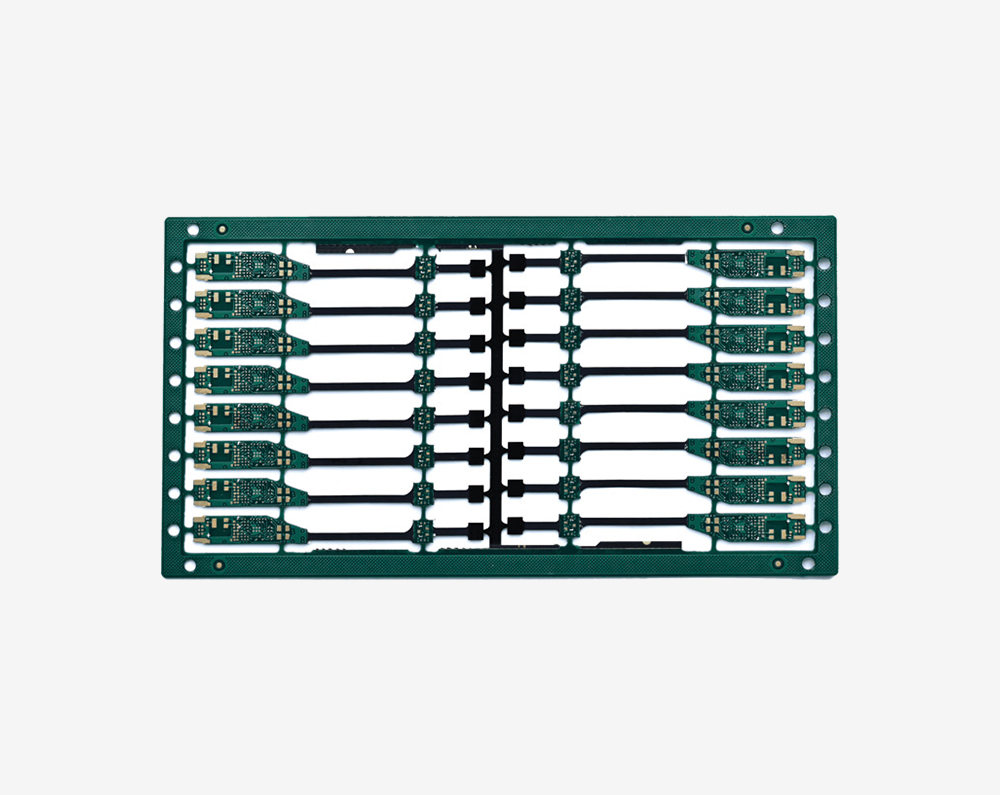

The copper thickness is 4.5OZ aluminum substrate, and the following difficulties will be encountered in the manufacturing:

1. Engineering design line width compensation: Due to the thickness of copper, the width must be compensated, otherwise the etching back line width is super worse, the customer is not acceptable, and the line width compensation must be stacked.

2. The uniformity of printing resistance welding: Because the copper thickness of the line is super routine after the graphic is etched, printing welding is very difficult, and customers are not affected by jumping or thick and thin customers. How to print a layer of green oil is also one of the difficulties.

3. Etching: It is necessary to meet the needs of customer drawings. The residual copper is not allowed, nor can it be scraped by the knife. The knife will scratch the insulating layer, causing the voltage resistance test to start with flames and leakage.

4. Mechanical processing: The aluminum substrate drilling can be allowed, but there are no burrs on the pores in the hole in the hole after drilling, which will affect the pressure resistance test. Milling shape is very difficult. The shape of the punch, the need to use high -end molds, the mold manufacturing is very tricky, which is also one of the difficulties for aluminum substrates. After the shape is flushed, the marginal demand is very regular, without any burrs, and does not touch the welding layer on the edge of the wounded plate. Generally, the use of military models, holes rushing from the line, the shape of the shape from the aluminum surface, the force when the line board is flushed, and the tensile is cut, and so on. After the shape of the shape, the plate warming should be less than 0.5%.

5. The entire production process is not allowed to wipe the aluminum base surface: aluminum base surfaces are contacting by hand, or some chemicals will change color and black. This is definitely not acceptable. Do not accept it, so the entire process does not touch the injury and does not touch the aluminum base surface is one of the difficulties to produce aluminum substrates. Some companies use passivation technology, and some are attached to the protective film before and after the heat wind are flat (tin spray) ... There are many tips, eight immortals cross the sea, each shows magical power.

6. Over -high voltage test: 100%high -voltage test for the demand for the aluminum substrate of the communication power, some customers need DC power, some need to communicate electricity, voltage demand 1500V and 1600V, it is 5 seconds, 10 seconds, and 100%printed boards are used for testing. Dirty, holes, and aluminum -based edges on the plate surface, sawtochia, and trauma any diced insulation layer will cause high -voltage tests to fire, leakage, and break through. The pressure test board is stratified and foam, and all refuse to accept it.