Time:2023-07-10Views:

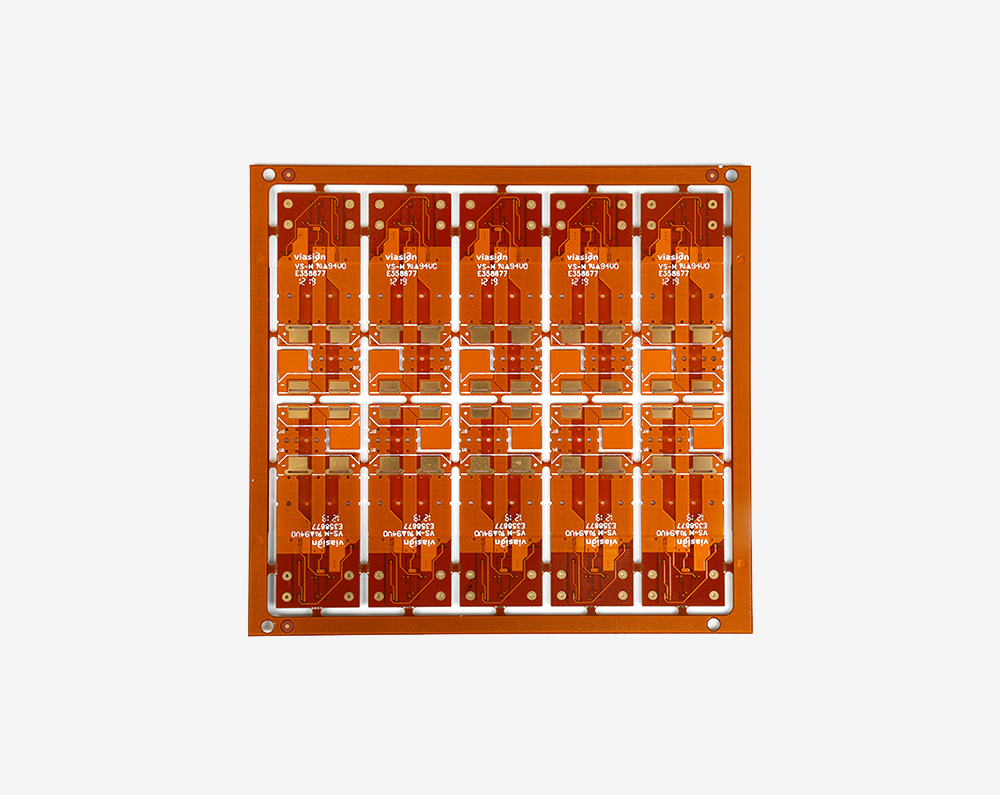

Circuit board sunk gold board and circuit board gold plating board is a common process in the production of circuit board today.

With the increasing integration of IC, the more IC's feet, the more dense. The vertical tin spray process is difficult to flatten the pads of thin pads, which brings difficulty to the slice of SMT; in addition, the life of the tin plate is very short. And the circuit board gold plating board just solves these problems. For the surface stickers, especially for ultra -small table stickers, because the flatness of the pads is directly related to the quality of the printing process of the tin paste, which has a decisive impact on the subsequent re -welding quality. It is often seen in the super small watch sticker process. During the trial stages, the influence of factors such as component procurement is often not welded immediately when the board comes, but often wait for a few weeks or even a month. Essence Therefore, everyone is willing to adopt. Besides, the cost of gold -plating is almost the same as that of lead -tin alloy boards.

What is gold plating

Global plating refers to the distinction between electroplating gold, electroplating golden board, electrolyte gold, electrical gold, electrical nickel gold board, and soft gold and hard gold (generally used as a golden finger). The principle is to dissolve nickel and gold (commonly known as golden salt) in chemical potion, immerse the circuit board in the electroplating cylinder and pass the current, and generate nickel gold plating on the copper foil surface of the circuit board. High hardness, abrasion resistance, and not easy to oxidize are widely used in electronic product names.