Time:2023-08-23Views:

FPC, as a connecting wire in electronic devices, mainly plays a role in conducting current and transmitting signals. When the signal transmission line is distributed within the outermost layer of the FPC, in order to avoid signal distortion caused by electromagnetic interference during the signal transmission process, the FPC will press a layer of electromagnetic shielding film after pressing the covering film, which serves as a conductive layer to shield against external electromagnetic interference.

The electromagnetic shielding film uses a mixed composite metal as the shielding material, which has excellent OSP performance and corrosion solvent resistance. In terms of shielding and winding characteristics, it is superior to similar products in the market. Electromagnetic wave shielding film is suitable for FPC soft printed circuits. It has high shielding, bending, and heat resistance. Suitable for connecting wires and circuits of electronic touch screens, with strong protection against electromagnetic interference!

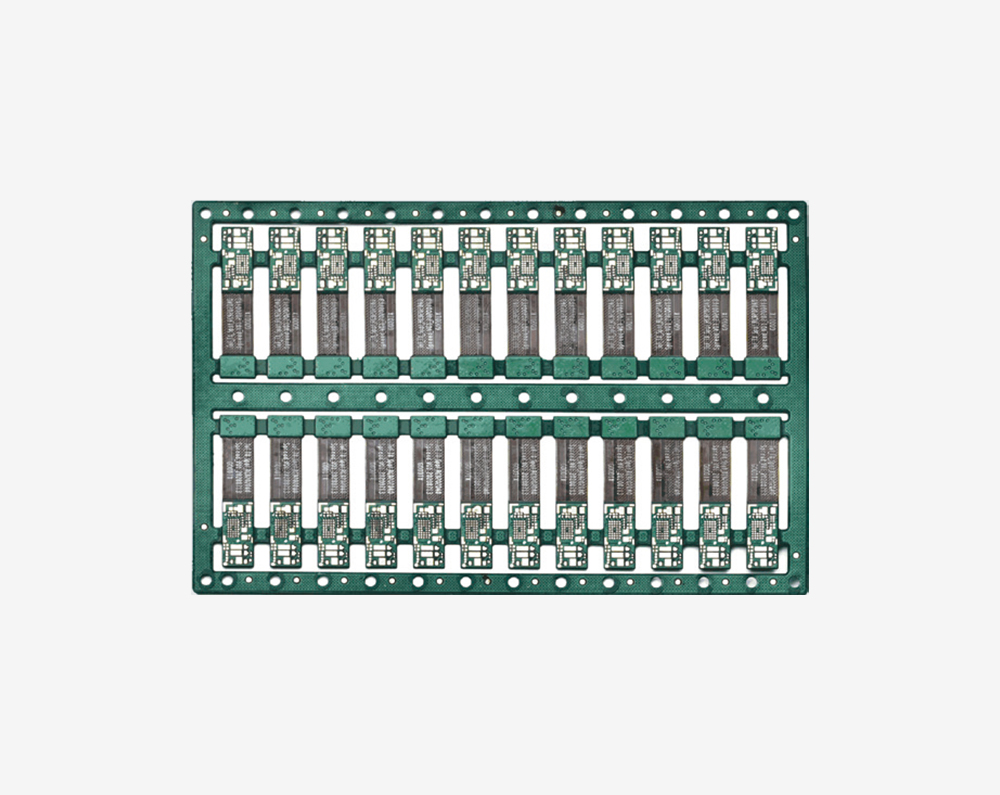

The performance of FPC flexible circuit boards needs to be verified through testing, and testing efficiency can be improved through the use of elastic micro needle modules,. In high current transmission, the shrapnel microneedle module can carry up to 50A of current, and the minimum response value in the small pitch field can reach 0.15mm. The connection is stable and reliable, with an average service life of up to 20W times, and the adaptability is extremely high.

Shielding film is an electromagnetic film, which is black in color and mainly used to shield external signal interference;

A covering film is a film that covers and presses onto the surface of a substrate. It is generally a polyimide resin, also known as PI, used for welding resistance and has little effect on signal shielding. Electromagnetic films are generally attached to the covering film, and the price of electromagnetic films is much higher than that of covering films.

FPC covering film, also known as CVL in the industry, has a main function similar to green paint on PCBs: 1) protecting copper foil from exposure to air and avoiding oxidation of copper foil; 2) Cover for subsequent surface treatment. Cover areas that do not require gold plating with CVL. 3) In the subsequent SMT, the solder resistance effect.