Time:2023-10-17Views:

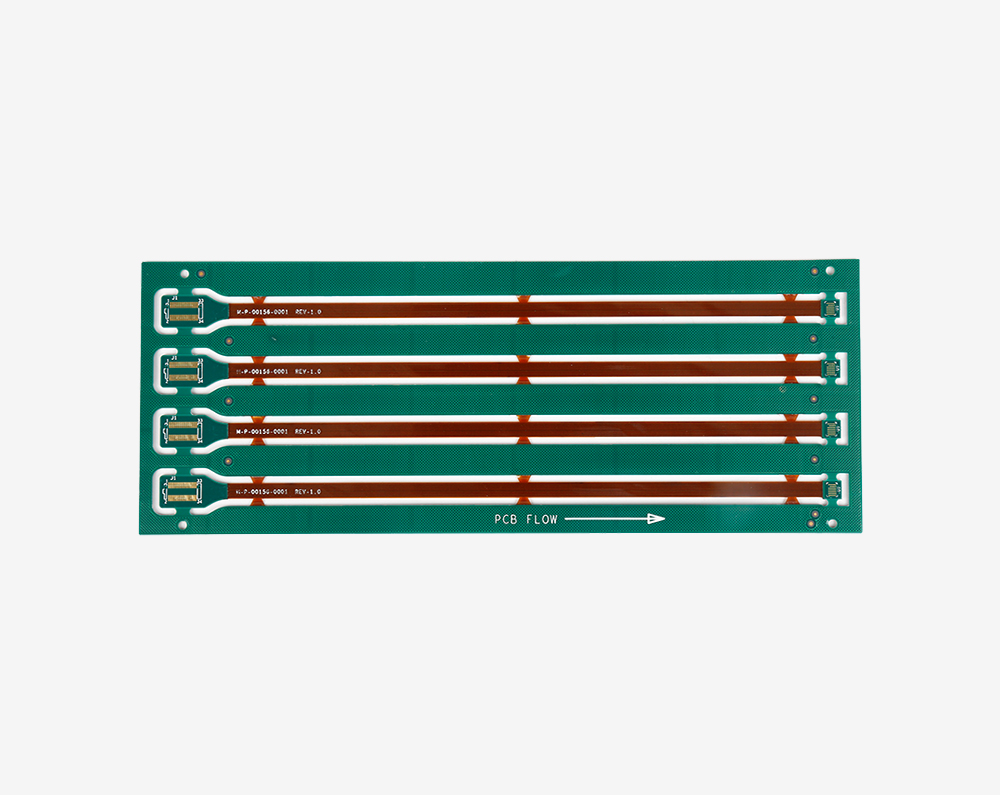

Cutting → Drilling → Applying Dry Film → Alignment → Exposure → Developing → Etching → Stripping → Surface Treatment → Applying Covering Film → Pressing → Curing → Surface Treatment → Nickel Gold Deposition → Printing Characters → Cutting → Electrical Testing → Punching → Final Inspection → Packaging → Shipping

According to the difference between one side covered with copper foil or two sides covered with copper foil, it is called single sided copper clad plate or double sided copper clad plate; According to the difference between copper foil and substrate film with or without adhesive, it is called adhesive coated copper plate or non adhesive coated copper plate. The structure of flexible copper clad plate is shown in Figure 3. The commonly used substrate films for flexible copper clad laminates include polyimide (PI), polyester (PET), polyethylene terephthalate (PEN:), liquid crystal polymer (LCP), and other polymer films. Copper clad board is mainly responsible for three functions: conductivity, insulation, and support on the entire printed circuit board. The performance, quality, processability during manufacturing, manufacturing cost, and manufacturing level of printed circuit boards largely depend on the performance of copper clad boards.