Time:2024-09-03Views:

Printed circuit board (PCB) is in the middle reaches of the electronics industry chain and is one of the core components of the electronics industry. The industry chain includes: raw materials-high-frequency and high-speed copper clad laminates-electronic components (PCB, etc.)-processing and assembly (SMT)-5G Molded end products.

Communication equipment is the hardware facility and physical manifestation that bears the communication system architecture. The communication system can be divided into access network (i.e. base station), bearer network (transmission) and core network (the part that processes data and connects to the Internet). Among them, the main communication equipment corresponding to the 5G system is the base station equipment (antenna system-AAU and Baseband unit-DU+CU), transmission equipment, core network equipment.

Communication circuit boards not only have strict requirements on the reliability, electrical performance, thermal performance and product quality of printed circuit boards, but also require product service life of more than ten years. Therefore, the certification of printed circuit board suppliers is strict and the entry barrier is high.

With the development of electronic technology, the PCB circuit board industry has also risen. The development of an industry will inevitably bring a wave of dividends. Many PCB proofing manufacturers have gradually appeared in the market. Today, PCB proofing manufacturers will tell you how to choose good quality PCB proofing products.

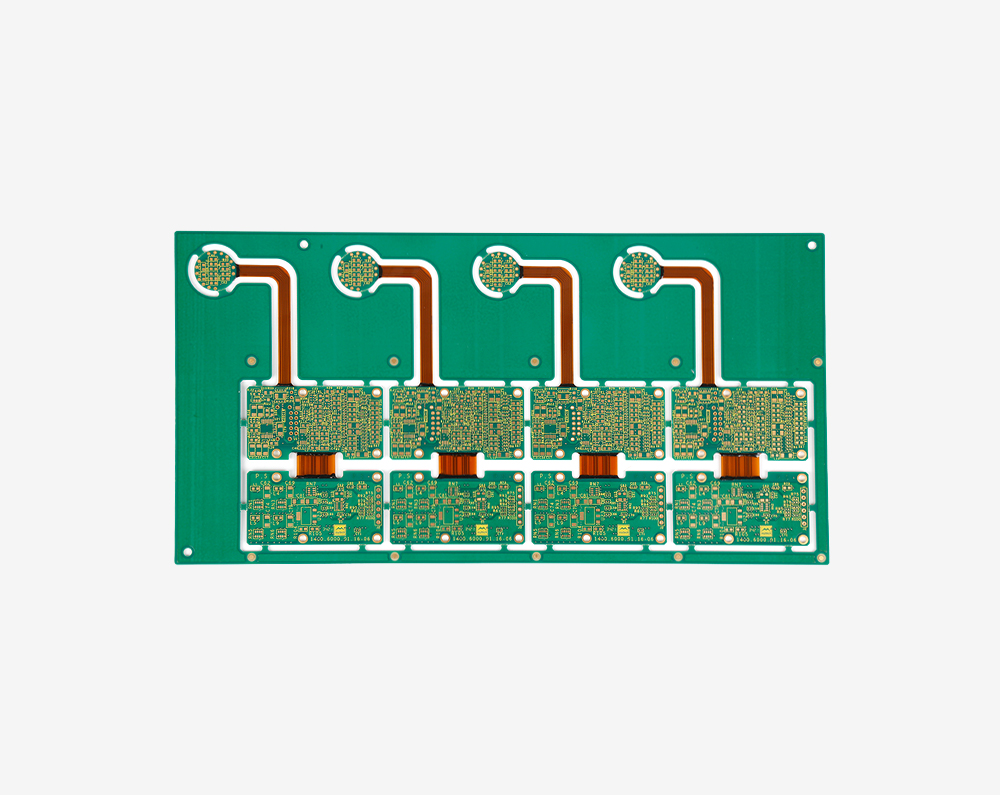

One is to distinguish from the appearance of the product. It is mainly observed from the thickness of the product, the size of the product and the color of the circuit board on the outside of the product. If the color is bright and covered with ink, it means that the quality of the PCB proofing product is good. In addition, pay attention to the details, such as whether the quality of the product's welding process is good, because it will directly affect the use of PCB products.

Second, it should be distinguished from the test results of the product. When choosing a PCB proofing product, the manufacturer should perform product quality inspection, such as checking whether the circuit has heat, open circuit, short circuit, etc., and observe whether the product can operate stably under high temperature and other environments. If there is no obvious fault in the test result, it means that the quality is better.

In short, to choose PCB proofing products, you must choose quality assurance (such as Jiefang, import raw materials, strict production control) in order to ensure the quality of electronic products.