Time:2021-08-16Views:

FPCB price is a puzzle for many PCB buyers. Many FPCB purchasers will also want to know how to calculate these prices when placing FPCB orders online. FPCB manufacturers will extract relevant manufacturing information according to the information description, and make a comprehensive judgment based on the manufacturing points in the Gerber file, such as line width, hole number, etc., so as to calculate reasonable price quotations to customers.

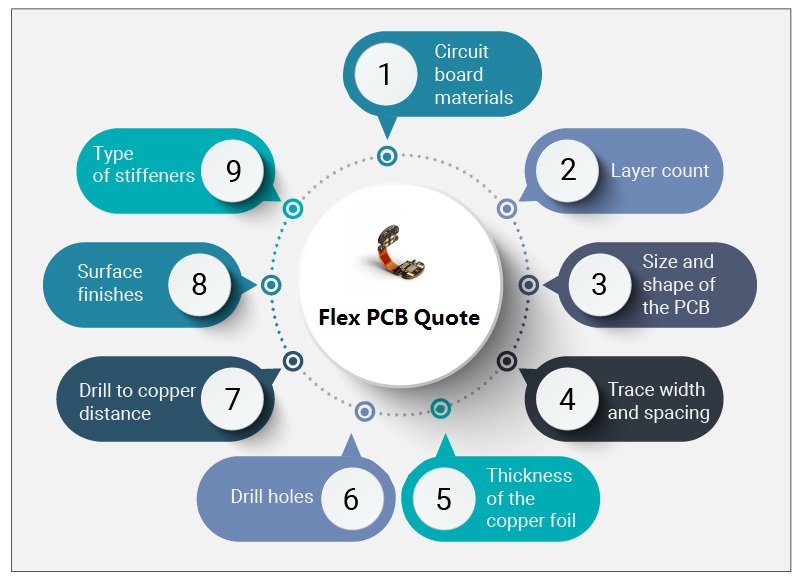

The factors influencing FPCB price

The factors influencing PCB price are as follows:

A. Material (thickness, copper thickness, brand), auxiliary materials.

For example, ordinary double-sided flexible board, the sheet material is generally PI, PET, etc., the thickness of the board varies from 0.0125mm to 0.10mm, and the thickness of copper varies from 1/3oz to 3oz, all of which cause a big price difference. At the same time There is also a certain price difference between material manufacturers, that is, different brands. This is the price diversity of material selection. The material also contains the composition of steel sheet, FR4, PIF, CCI copper foil, reinforcement material and other auxiliary materials.

B. Surface treatment method

Different Surface treatment method also result in different costs. For example, we use immersion gold, immersion tin or OSP, requires the accuracy of the shape, and the use of wet film lines or dry film lines, will result in different costs.

C. Processing capacity (line width, line spacing, impedance, gold finger)

Under the same requirements and process, if our flexible circuit board itself has different design difficulties, it will also cause different costs. For example, there are two kinds of circuit boards, one of which has a hole on the board that exceeds the standard, and the other that is within the normal range. The drilling costs thus formed also vary. For another example, one type of line width and line spacing is greater than 0.1mm, and the other is less than 0.1mm, which will also cause price differences, because the more difficult boards have a higher scrap rate, and the cost will inevitably increase, resulting in different prices.

D. The special request

The level of customer requirements will directly affect the yield of the board factory. For example, a board according to IPC-A-6013, class 1 requires a 98% pass rate, but according to class 3 requirements, it may only have a 90% pass rate, resulting in different costs for board manufacturers, and finally leading to changes in product prices.

E. Different plating methods

The local electroplating price is about 15% higher than the overall electroplating price.

F. Surface treatment of gold finger part

The price of gold plating is about 5% lower than that of tin plating.

G. The level of defective rate in the production process of FPC also determines the unit price of FPC.

H. Some designs can communicate with R &D to reduce costs.

For example, Is it possible to change 8-layer 2 + N + 2 HDI FPCB into 8-layer 1-step board?

This is why the FPCB service provider requests Gerber data. Only complete FPCB making information and parameter description can we get an accurate quotation, otherwise, the quotation will not be accurate to the customer.

FPCB quotation composition

FPCB quotation is generally composed of engineering cost + circuit board production cost + tool cost + test cost. FPCB manufacturing fee is calculated in square meters, except for samples.

Order quantity/delivery date

1) The less quantity, the more expensive the price is, because even if one is to be manufactured, the board factory must also produce engineering data and produce the film. FPCB production process has dozens of processes, and each process is essential.

2) Delivery date: the data to be delivered to FPCB Factory shall be complete (Gerber information shall be clearly written, number of layers of board, material, thickness, surface treatment, ink color, character color and some special requirements).

The delivery time of ordinary FPCB samples depends on the number of layers. One side usually takes three day, two sides usually take five to seven days, and multi-layer takes several to ten days.

How to find the right supplier?

Determine the performance requirements of PCB electronic products

First, it is necessary to analyze the market positioning of the company's products. The most basic concept is to choose high-quality products for medium and high-end products and pursue the price of low-end products. However, it is very important for the purchasing staff to master the development cycle of electronic products. In the prototype design stage, the overall efficiency is the highest, the price is second, and the quality is in the middle.

Therefore, it is necessary for buyers to find FPCB suppliers who can provide fast FPCB prototypes, such as the fast FPCB Factory in the market.

However, in the small-batch and batch production stage, FPCB procurement should be grasped from the quality and delivery time. Buyers need to understand the design structure, precision requirements, line width, line spacing, layers, copper thickness, and other important indicators of Flexible Printed Circuits.

For FPCB board of electronic products that need special technology, we should find a high-quality PCB manufacturer.

XCF FPCB manufacturer serves customers in many countries around the world, and its products cover medical electronics, industrial & instrumentation, communications, power supply, security, automotive electronics, military & Aerospace Electronics, We are well aware of the relevant manufacturing requirements in variable fields and strict enough by the industry specifications. XCF FPCB helps you to purchase a high-quality FPCB one-stop. You need not worry about dealing with various kinds of suppliers' bad problems and always have defects that can not be solved. In XCF FPCB we help you purchase easily and simply, shorten your procurement cycle, reduce your cost. Everything from now on, contact us for quotation, we will reply to customers the first time, and bring you a satisfied customer experience.